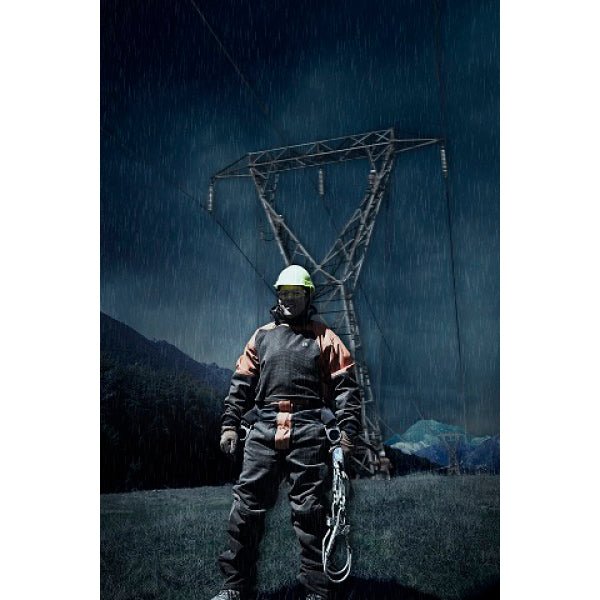

Not every garment solution is off the shelf, some require much more research into fabric and design. When Northpower came to Swazi with challenges around their requirements for Blasting and Wash-down garments for work on the country’s high voltage power pylons, it compelled our Design Team to think out of the box, to be innovative not only with the design of the garments, but also with the fabric we would ultimately build.

Three main considerations were integral to the design process.

1. From a health and safety approach, workers needed protection from arc flash (which can reach temperatures exceeding 5000°C), as well as withstanding the rigours of sustained periods of work in extreme weather conditions where hypothermia could result.

2. Workers needed to have a high degree of flexibility, freedom of movement and comfort in all weather while working at extreme heights on the power pylons.

3. From the contractors perspective, as well as fully meeting the criteria of the first two considerations, an increase in productivity, extra durability and a fit for purpose garment were desired outcomes.

The PPE Northpower had been using were a mix of purpose built jackets and pants with a combined weight in excess of 20kgs. After several site visits to research ergonomics, workplace practices along with the dynamics of garnet blasting at high pressure, the Swazi Design Team came to the conclusion a more flexible “one-piece suit” would invariably increase not only the longevity of the PPE but dramatically enhance worker safety, flexibility and hence productivity.

Once all this field data had been collected, the fabric could now be developed. The suits would have to withstand not only arc-flash incidents, but also provide protection from garnet blasting... and the harsh New Zealand weather. The solution was a 3-layered SWAZI AEGIS® fabric, providing both an inherently flame retardant and arc-resistant shield. For the face, or outer layer, we used Nomex®, bonded directly onto a PFTE (Polytetrafluoroethylene) microporous membrane which allows moisture vapour to pass through one way but does not allow water to penetrate, making it waterproof, windproof and breathable. The face also incorporates a 'grid pattern' of carbon anti-static fibres The third layer is a Nomex® mesh inner, laminated to protect the membrane. Finally, once developed, we had the fabric independently tested by the Kinectrics Laboratory at Toronto in Canada. It has a rating of 13 Cal/cm2 , plus a Heat Attenuation Factor of 78%.

The garments Swazi® makes from Arc AEGIS® means staff are able to work at optimum levels, so safety, comfort and productivity are all operating at maximum output. The weight of the suit is just on 2.3kgs.

“You can really see the difference when someone is climbing in a Swazi Arc Suit. There are no restrictions on movement, so it gives far greater mobility and manoeuvrability to get in to those tricky positions. In our old PPE we would go through a set every 6 weeks. The Swazi Arc Suits are not only perfoming extremely well, their durability is running at an added 1100% more than our previous PPE – an investment our Accountant is extremely happy with!”

Kapiti Northpower

Using the Swazi AEGIS® fabric we have also created wet weather Raincoats, Bib Overtrousers and Overpants. These garments are suitable for all applications which occur around electrical installations, offering protection from the harmful affects of arc flash, as well as providing extreme comfort in inclement weather.

Footnote: The Swazi Arc Suit was recognised for it's innovation, becoming a finalist at the prestigious Delloite Energy Excellence Awards. From left Jeremy Collins (Kapiti Northpower), Davey Hughes (Swazi), Lionel Tito (Kapiti Northpower)

Contact our Swazi Branded Apparel Team today if you require garments made to your specifications to meet your industry requirements. We understand business.

branded@swazi.co.nz

For your copy of The Swazi Arc Suit brochure please visit our website here

Share: